Our business activities rely on precious resources. We live up to our responsibility by improving our processes and products so that they require fewer and fewer resources and by adopting circular approaches wherever possible. With recycling we recover large quantities of precious metals, which reduces the need for primary extraction.

Resources are precious to us

Targets and Key Figures

60% share of recycled platinum group metals (PGM) processed in our plants in 2022

60% of PGM and 23% of gold and silver volume processed in our plants are secondary material. In addition, we aim to increase the proportion of recycled precious metals in our products.

€300m investment in recycling capacities until 2026

We are continuously expanding our worldwide recycling capacities and capabilities. This allows us to close the loop for further waste containing precious metals. Between 2018 and 2026, we will have invested a total of 300 million euros in further capacities in Europe, North America, and Asia.

-98%* carbon footprint of recycled vs. primary precious metals

Many of our precious metal products are returned to us at the end of their lifetime. By making new products out of the recycled fine metal, we are continuously keeping recovered precious metals in the loop.

Precious Metals Recycling and Refining

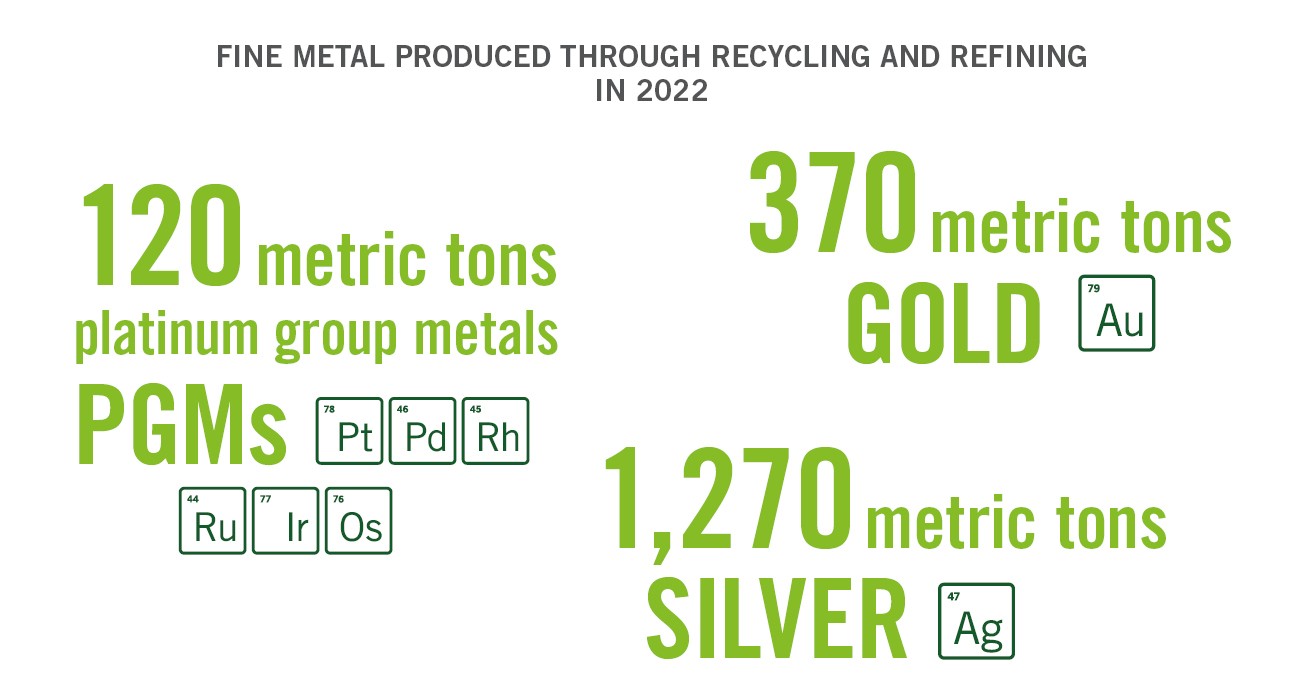

We refine and recycle all eight precious metals and rhenium from primary and secondary sources. With 11 facilities in six countries worldwide, we not only maintain close proximity to our customers but also achieve shorter transportation distances.

We use state-of-the-art pyrometallurgical and hydrometallurgical processes to recover precious metals from end-of-life materials to the maximum extent possible.

Major Projects and Examples

Iridium: scarce but indispensable for producing green hydrogen

One of the most promising technologies for producing zero-carbon (green) hydrogen is proton exchange membrane (PEM) water electrolysis. About 70 gigawatts (GW) of PEM electrolysis capacity are expected to be built worldwide by 2030. Every gigawatt currently requires an average of 400 kilograms iridium in the form of an electrocatalyst. 70 GW of capacity would therefore need about 28 metric tons of iridium, which is more than double the quantity available. Heraeus Precious Metals can help in two ways. First, we have designed an innovative iridium catalyst that only requires about 100 kilograms of iridium per gigawatt of PEM capacity, reducing the total amount of iridium needed to 7 metric tons. Second, we are continuously advancing our recycling of iridium from spent electrolyzers. Recycling, which is far less carbon-intensive than primary extraction, will help make green hydrogen truly green along its entire lifecycle.